home

Your print – our mission

Qualität & Service von Polywest

POLYWEST garantiert Qualität und Knowhow der zwei Unternehmensbereiche ‚Sleeves für den Flexodruck‘ und ‚Formteile (GFK und CFK)‘. Wenn Sie diese Begriffe kennen, sind Sie bei uns richtig. Seit 1987 hat sich POLYWEST zum weltweit führenden Systemanbieter für Druckformen, Sleeves und Adapter entwickelt. Neben einem Sleeveservice bieten wir unseren Kunden auch umfassende Beratung an, damit Sie vom POLYWEST Knowhow profitieren können. Immer wieder betreiben wir Innovationen mit Forschungsinstituten und Industriepartnern, sodass neue Technologien und Materialien zum Nutzen unserer Kunden voran getrieben werden.

Polywest Vertretungen

POLYWEST wird international von über 60 Vertretungen repräsentiert. Erfahren Sie mehr über unsere Partner und Ihre direkte Verbindung zu POLYWEST international.

Unsere berater in …

- Nord-amerika

- Süd-amerika

- Europa

- Afrika

- Asien

- Australien

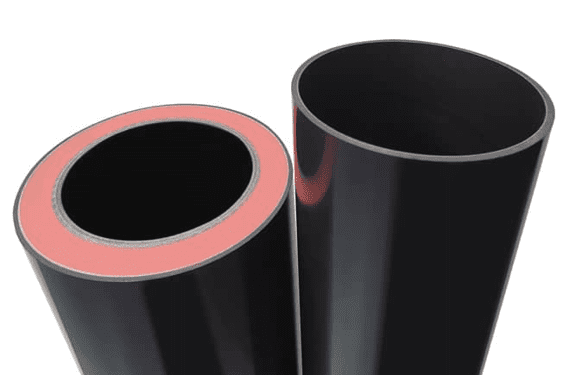

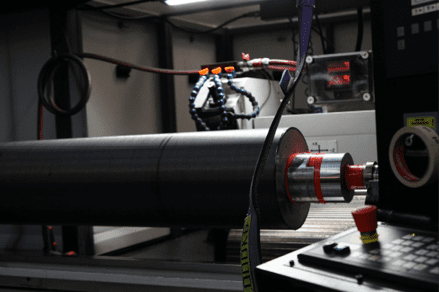

SLEEVES

POLYCARBON

POLYBRIDGE

Base & Protect

Produkte & service

Innovatives Produktdesign und unser stetiges Streben, die Bedürfnisse unserer Kunden optimal zu erfüllen, prägen unsere Arbeit. Wir passen unsere Produkte den neusten Anforderungen des technischen Wandels an und produzieren individuell nach Ihren Vorstellungen.

Als einer der führenden Sleeve-Hersteller weltweit

sind wir Impulsgeber für die permanente Weiterentwicklung der

Sleeve- und Adaptertechnologie.