Products

Your print – our mission

Products

Since its foundation, POLYWEST has continuously expanded its product range.

Today, POLYWEST is a system provider focusing on printing forms, sleeves, adapters, consulting services and sleeve services. We have a wealth of experience in various areas, which are precisely coordinated to achieve high-quality results.

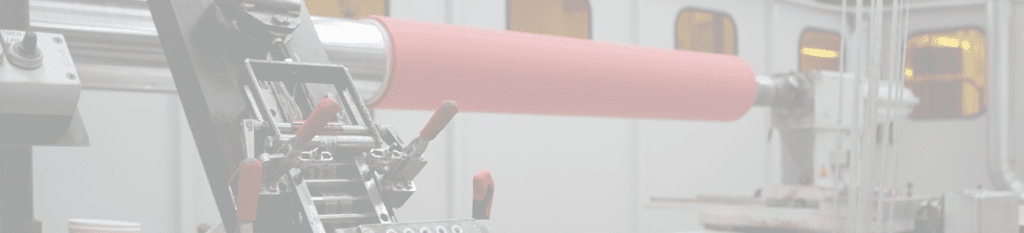

Sleeves

Ideal for the HD flexo printing. POLYWEST sleeve technology offers durability with outstanding performance.

Polycarbon

POLYWEST offers a three-stage system for flexo printing with the POLYCARBON adapters.

Polybridge

Adapters for special applications. POLYWEST provides – with the POLYBRIDGE adapters – a product series of high quality adapters for special applications.

Base & Protect

The basic sleeves for various applications & protective sleeves for the optimal protection of your anilox rollers.